Previous

Next

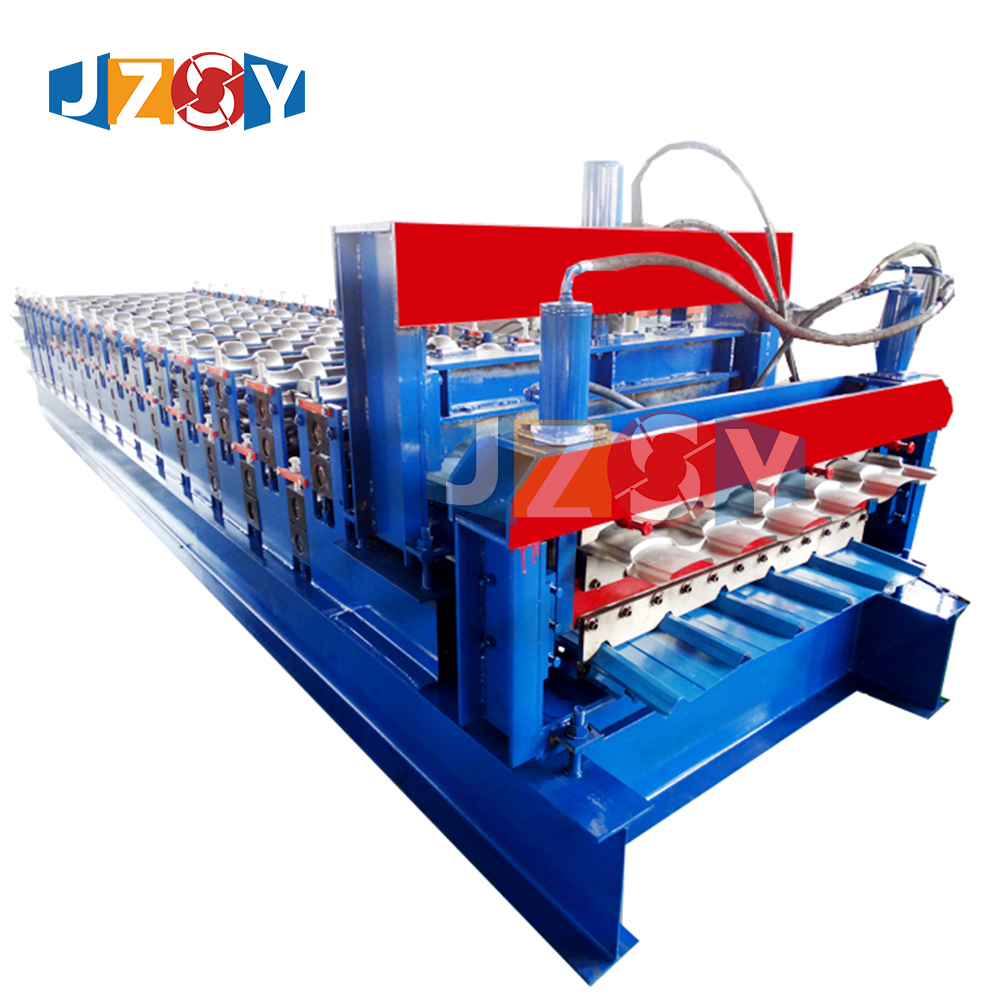

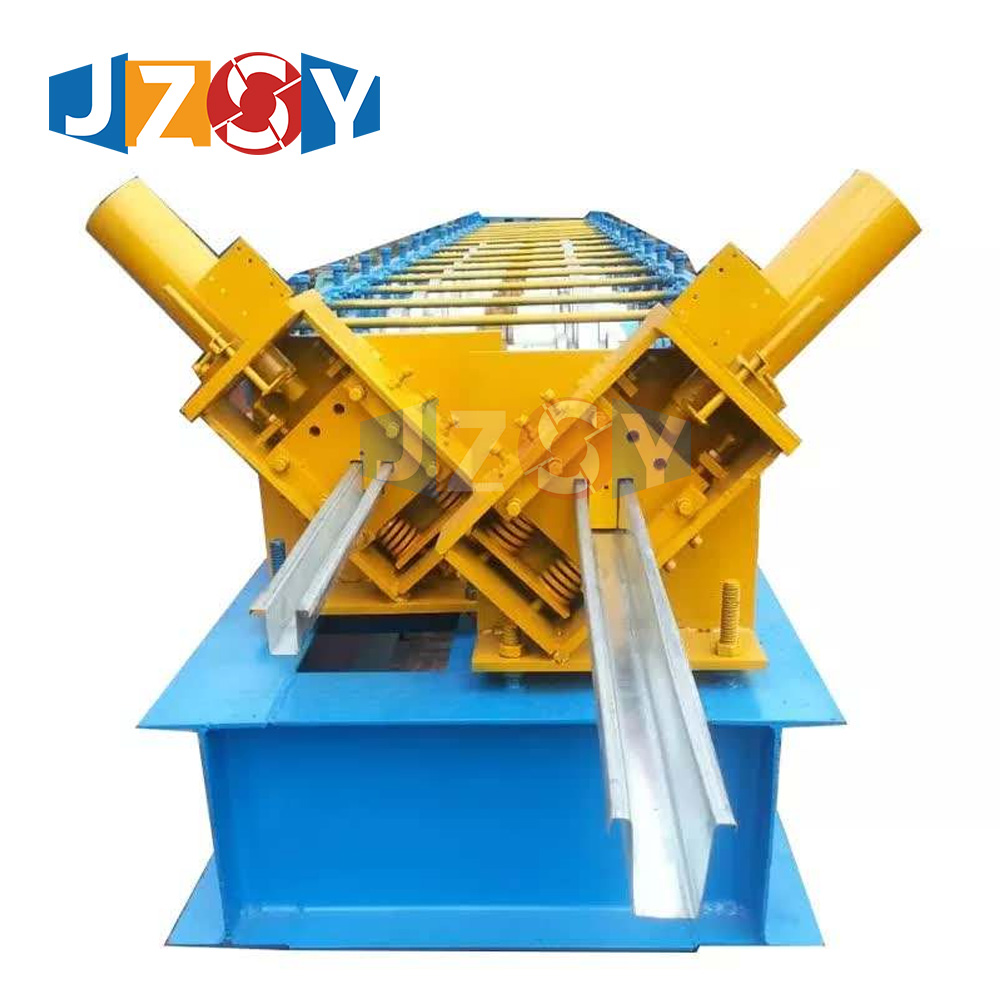

EPS sandwich panel roll forming machine

Features

EPS core technology: Unique EPS core material design provides excellent heat preservation and insulation performance.

Efficient productivity: Advanced manufacturing technology quickly forms a complete sandwich structure and improves production efficiency.

Multi-layer design flexibility: The multi-layer sandwich structure can be customized to adapt to different project needs and increase the versatility of the building.

Durable material selection: High-quality materials are used to ensure the stability and durability of the sandwich panel.

EPS sandwich panel roll forming machine

Parameters of Sandwich part:

Parameters of Sandwich part:

| Type | Specification | ||

| 1 | Sandwich part | Fill material | Polystyrene |

| Density | 16-20 kg/m3 | ||

| Thickness | 50-250 mm | ||

| Length | 6 m | ||

| 2 | Glue | Strength | >10 N/cm2 |

| Viscosity | A: 0.4~0.7 Pa•sB: 0.3~0.6 Pa•s | ||

| Component | A:B = 1:1.5 | ||

| Foaming time | 20-40 s (room T) | ||

| Solidify time | 50-70 s (room T) | ||

| Adhesive area between panel and material | > 85% | ||

| 4 | Control system | PLC | Delta |

| Counter | Omran | ||

| Language | As your need | ||